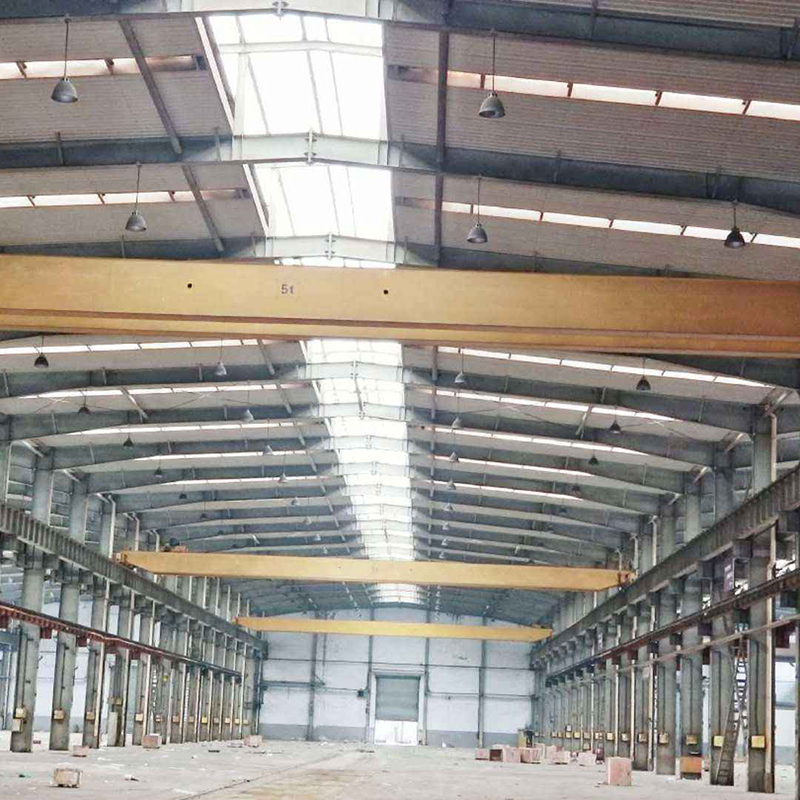

In the construction of steel structure, it is necessary to find a good manufacturer first. After all, there are many problems to be solved in details about the quality of steel structure, and the quality of products is also very important. How can we do well in details for the construction of steel structure?

Light steel structure is mainly H-shaped solid web column beam structure, so the surface treatment and painting process is relatively simple, and it is very easy to complete professional assembly line operation.Shot blasting technology, raceway or suspension feeding method shall be selected for surface treatment.Spray coating is generally made by hand, combined with suspension shot blasting, but also semi mechanized production line.The surface treatment before spraying is very important for the actual effect of anticorrosion of component top coat, and the thickness and symmetry of the paint layer will immediately endanger the anticorrosion characteristics of the component. In the whole process of this kind of seemingly detailed work, every construction team should be careful and careful, and it is not necessary to look down on this kind of detail, maybe we can make a decision on this small point

What is the standard of steel structure construction

1. the height of the fixed anchor bolt is different, the column base plan is not measured in advance, and the embedded parts are moved to produce column deviation, which should be measured first and then buried.

2. during the installation of steel poles, the safety operation regulations are violated. The steel poles are erected one by one. On the same day, there is no way to produce a solid structural module. As the wind blows, it will collapse.Such safety production accidents occur several times and should be definitely prevented.After the installation of steel member column and beam, adjust the flatness and slope gasket of steel beam as early as possible, then close the column base, and secondary grouting density.

3. steel members are not installed easily according to the construction sequence.During the installation of components, it shall be carried out in strict accordance with the sequence of installation and processing technology, and solid framework modules shall be generated on that day. When they cannot be generated, cables and wind ropes shall be added to fix them, so as to avoid collapse safety accidents.

Post time: Jun-08-2020