What is the structure of rock wool color steel plate?

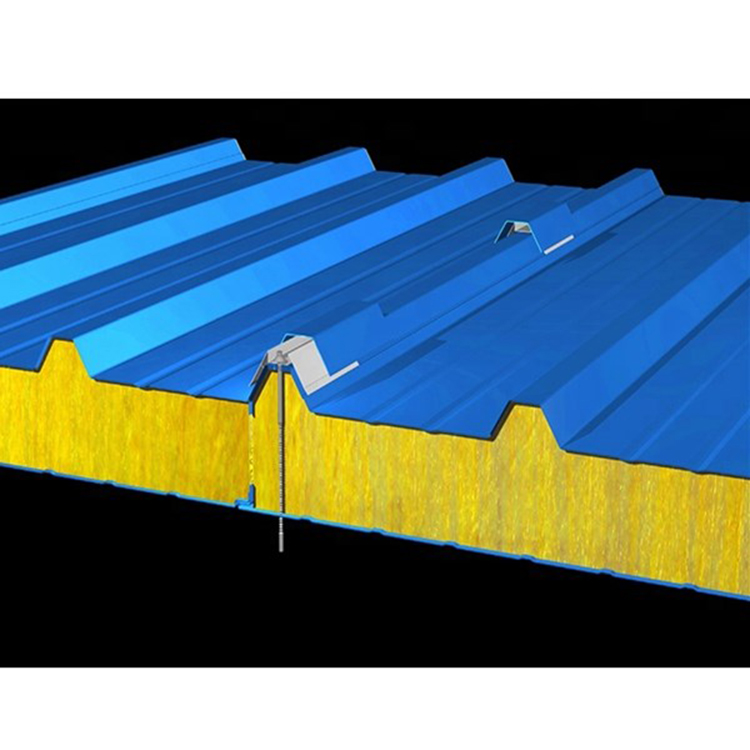

1) Upper and lower surface: galvanized color steel plate with thickness of 0.4-0.8mm.Aluminum zinc color steel plate or galvanized steel plate can also be used.The steel plate is first rolled by the forming machine and then compounded with rock wool factory.

2) Rock wool core material: the rock wool block with a density of 120kg / M 3 is laid in a staggered way, and its fiber trend is perpendicular to the upper and lower surfaces of the sandwich panel, and closely connected to enrich the entire vertical and horizontal surfaces of the sandwich panel.High strength foaming agent is used for bonding between rock wool blocks and between rock wool and upper and lower steel plates to form a whole. Excellent production technology ensures that a strong adhesive force can be generated between high density rock wool heat insulator and inner wall of metal plate, so that rock wool sandwich plate has a good rigidity.

Post time: Jun-05-2020