Basic analysis of the prefabricated construction industry

With the rapid development of science and technology, human beings are constantly upgrading their construction methods. Since the beginning of the 20th century, the prefabricated building has attracted wide attention, and in the trials of Europe and the United States, it has shown the advantages of fast construction speed and low production cost.

In China, the prefabricated building is still in its infancy, but according to the “Building Industry Modernization Development Outline” issued by the Ministry of Housing and Urban-Rural Development, it is planned that by 2020, the proportion of prefabricated buildings will account for more than 20% of new buildings, and by 2025, prefabricated buildings will occupy new buildings. The proportion is more than 50%. As a result, the prefabricated building became the focus of attention throughout the construction industry at the beginning of 2019.

It is understood that the so-called “assembled building” is a new type of building that combines new assembled construction technology with sustainable technology. In the construction process, the system is designed by system design, modular splitting, factory manufacturing, on-site assembly, industrialized construction method in the factory for processing and on-site assembly design. The prefabricated building is different from the “extensive construction” mode of traditional architecture. It is more like “manufacturing” an industrial product. It is prefabricated in the form of assembly line. After being transported to the installation site, it will be built like a building block. Get it up. The prefabricated building has the characteristics of sustainability, not only fireproof, insect proof, moisture proof, heat preservation, but also environmental protection and energy saving.

In the future, the scale of China’s fabricated construction market will exceed 1.4 trillion

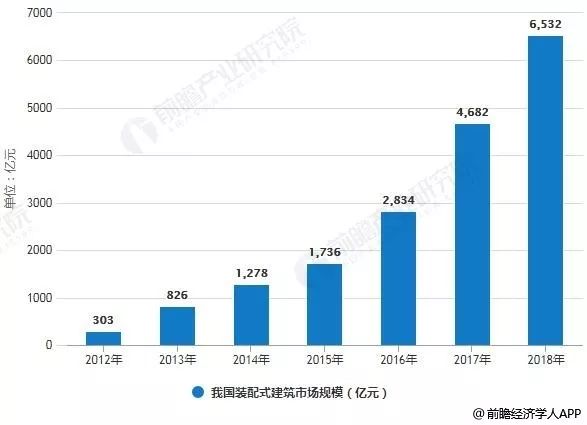

From the perspective of the layout of industry reform and development, China’s construction industry has advanced a lot toward the goal of industrial modernization, and the prefabricated buildings have shown a booming development. According to the statistics of China’s prefabricated construction industry market prospects and investment planning in-depth analysis report released by Prospective Industry Research Institute, the scale of China’s fabricated construction market in 2012 was only 30.3 billion yuan, showing a year-on-year growth. By 2016, the scale of China’s fabricated construction market reached 283.4 billion yuan, and it has been growing at a high speed. As of 2017, China’s fabricated construction market grew to a size of 468.2 billion yuan. It is estimated that the scale of China’s fabricated construction market will exceed 650 billion yuan in 2018, reaching 653.2 billion yuan.

In February 2016, the State Council issued the “Several Opinions on Further Strengthening the Management of Urban Planning and Construction”, clearly stating that it is necessary to vigorously promote prefabricated buildings and build a state-level assembly-type building production base. Increase policy support and strive to use 30 years or so to make assembly buildings account for 30% of new buildings. Immediately after the end of 2017, the Ministry of Housing and Urban-Rural Development issued a notice to move the prefabricated building from the pilot demonstration to the comprehensive promotion phase. With the support of national policy level, China’s fabricated construction industry will continue to maintain a high-speed development trend.

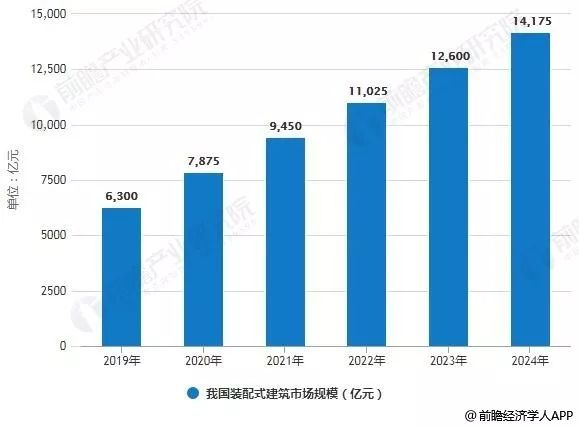

Therefore, according to the reference cost of the prefabricated building cost issued by the Ministry of Housing and Urban-Rural Development, based on 2,500 yuan / square meter (taking into account the different impact of rising technical level and price increases on the price level, assuming the cost of the next few years unchanged), based on real estate The new building area will replace the newly built urban construction area, and by 2024, the scale of China’s fabricated building market will exceed 1.40 billion yuan.

Analysis on the development prospect of China’s fabricated construction industry

1. Policy dividend

In March 2017, the Ministry of Housing and Urban-Rural Development issued the “13th Five-Year Planned Building Action Plan”, “Assembly Building Demonstration City Management Measures” and “Assembled Construction Industry Base Management Measures”, clearly stating that by 2020, The proportion of newly-built buildings in the country’s prefabricated buildings has reached more than 15%, of which the key promotion areas have reached more than 20%, the active promotion areas have reached more than 15%, and the encouraged areas have reached more than 10%. By 2020, cultivate more than 50 prefabricated building demonstration cities, more than 200 prefabricated building industrial bases, more than 500 prefabricated building demonstration projects, build more than 30 prefabricated building technology innovation bases, and give full play to demonstration leading and driving actions. .

In June 2017, the three national standards such as “Technical Standards for Prefabricated Concrete Buildings”, “Technical Standards for Assembled Steel Structures” and “Technical Standards for Assembled Wood Structures” issued by the Ministry of Housing and Urban-Rural Development were officially implemented.

In July 2017, the Department of Building Energy Conservation and Science and Technology of the Ministry of Housing and Urban-Rural Development issued the “Notice on Doing a Good Job in the Training and Implementation of Standards for Assembly-type Buildings”, requiring construction departments, construction committees (regulation committees) and construction corps throughout the country. The relevant units will vigorously publicize, train and implement the prefabricated buildings in accordance with the standards.

In November 2017, the Ministry of Housing and Urban-Rural Development issued the “Letter on Identifying the First Demonstration Buildings and Industrial Bases for Prefabricated Buildings” and announced 30 prefabricated building demonstration cities (including Beijing, Shanghai, Tianjin, Shenyang, Nanjing, Hangzhou, Hefei, Zhengzhou, Chengdu, etc., awarded 195 units the title of “Assembled Building Demonstration Industry Base” to further promote the implementation of prefabricated buildings.

On February 1, 2018, the Ministry of Housing and Urban-Rural Development issued a notice approving the “Assembly Building Evaluation Standards” as a national standard, and the original national standard “Industrial Building Evaluation Standards” was abolished at the same time.

2, the advantages of assembled buildings are obvious

Compared with the traditional construction method, the prefabricated building has many advantages such as energy saving and environmental protection and high building efficiency. The first is the environmental protection of buildings. The prefabricated buildings reduce the dust pollution during construction and the construction waste pollution during the residential recycling process. The efficient construction method brings about resource conservation, and the flexibility of prefabricated component production is also green building materials. The use provides space to ensure its energy efficiency. Secondly, the speed of the building is fast. The efficiency of the factory’s flow is much higher than that of the workers. The construction period of the prefabricated building is one-third of the traditional construction period. The rapid construction period will put the financial cost of the construction enterprise. Reduce and promote the good operation of the company. In addition, standardized production is less affected by external conditions such as climate, which can improve the safety level of assembly and construction. The advantages of stable quality will also lay the foundation for the capital turnover of construction enterprises and the establishment of corporate brands.

3. BIM technology innovation promotes industry transformation and upgrading

BIM is based on various information data of construction projects, and establishes a three-dimensional building model to simulate the real information of buildings through digital information simulation. This model includes both the information model of the building and the model of the management behavior of the building engineering. It can be combined by the sharing and transmission of information to provide a basis for the design team and the construction team to work together to improve the construction efficiency. Save costs, shorten the construction period, and effectively realize the life cycle management of the building. Under the concept of big data, the standardization and dataization of prefabricated buildings not only facilitates management operations, but also fits the current hot VR decoration concept. The combination of BIM technology innovation and fabricated building technology will help solve the pain points of construction efficiency, quality and safety, cost control in China’s construction industry, and accelerate the transformation and upgrading of traditional buildings in China to the assembly-building industry.

4. Steel structure assembly buildings are widely used

Steel structure buildings have obvious advantages over traditional construction methods:

First, the steel structure can realize the standardized production of the steel components and the components of the supporting structure, the quality is easy to guarantee, and the self-weight and light on-site assembly construction not only saves labor, but also saves safety and environmental protection;

The second is to significantly reduce dust, noise pollution and resource consumption. Steel can be recycled and recycled, reduce construction waste, and can be used as a national strategic resource reserve;

Third, the steel structure is “high and light”, and it is easy to build complex structures such as high-rise buildings and large-span buildings, and improve land use rate and indoor room rate;

Fourth, the seismic performance is excellent, the material is lightweight and the structure is safer. Since the State Council issued the Green Building Action Plan, reducing resource consumption, focusing on energy conservation and environmental protection, and promoting green buildings have become the consensus of the whole society. The development of building industrialization and assembly is an important way to implement green building action plans. The characteristics of chemical production and assembly construction make it one of the most environmentally friendly and mature green buildings, which will be widely used.

Post time: Sep-24-2019