Question 1: what are the advantages of rock wool in building thermal insulation and fire prevention? What problems should be paid attention to when doing a good job in external wall thermal insulation and fire prevention?

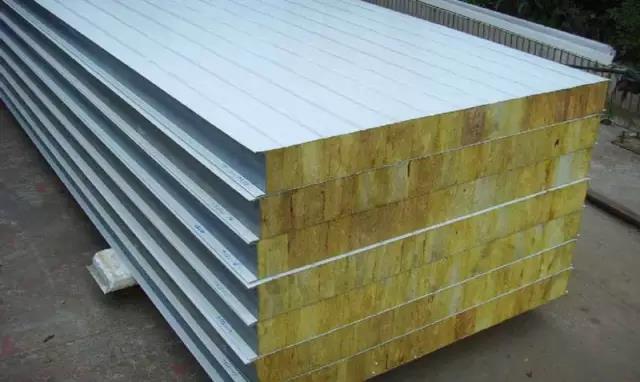

Answer: building fire is a very terrible thing that nobody wants to see.Rock wool itself is silicate fiber inorganic material, non combustible, rock wool with thermal insulation, belongs to A-class fireproof material.In the use of rock wool fire insulation board, not only to ensure the effect of thermal insulation, but also the fire performance in line with the fire standards.

To do a good job in the fire protection of external wall insulation, we need to do the following: one is to strictly implement various fire laws and regulations and strictly implement the fire control system.Select good thermal insulation materials, the use of thermal insulation materials at the primary stage of fire prevention measures, the use of thermal insulation materials in the intermediate stage of the construction process monitoring, to prevent the possibility of fire; insulation materials made into the external wall insulation system, after the insulation system, the correct use and Prevention of fire.

Question 2: to use rock wool products with good thermal conductivity and fire resistance, does it mean that the tensile strength, water absorption and durability requirements must be reduced?

Answer: the high-quality rock wool produced in China can fully meet all the requirements of tensile strength, water absorption, durability and thermal insulation performance, and belongs to A-class non combustible materials.In most applications, the thermal insulation performance of rock wool is comparable to that of polystyrene board, and even exceeds that of polystyrene board in some applications.

Question 3: what is the external wall thermal insulation system? Can rock wool be applied to the external wall thermal insulation composite system?

Answer: external thermal insulation system refers to a kind of engineering practice that uses certain fixed methods (bonding, mechanical anchoring, spraying, pouring, etc.) to fix the thermal insulation materials with low thermal conductivity (good thermal insulation effect) with the building wall, so as to increase the average thermal resistance of the wall, so as to achieve the effect of thermal insulation or thermal insulation.

Rock wool external wall insulation system has the advantages of low thermal conductivity, good air permeability and high combustion performance. It can be applied to the energy-saving and thermal insulation engineering of new, expanded and rebuilt residential buildings and public buildings, including external insulation of external wall, non transparent curtain wall insulation and fireproof isolation belt of EPS external insulation system.In order to improve the fire protection function of the building exterior wall, it should be used with the insulation materials whose combustion performance can not reach a level.Rock wool is an excellent thermal insulation product for exterior wall and exterior insulation composite system. Moreover, due to its non combustible performance, rock wool is also a building fire safety solution, which is regarded as the preferred material and solution for high-rise buildings.The flammability of foam insulation products will cause great risk and damage to people and property. Therefore, Europe and the United States are not allowed to use this material in high-rise buildings.

Question 4: in Europe, such as Germany, does rock wool only occupy a small market share in the application of all external insulation composite systems?

Answer: in Germany, for high-rise buildings above 22 meters, the market share of rock wool in the composite system of external wall and external insulation is 100%.Rock wool has a market share of 5.6% in all external wall and exterior insulation composite system applications, but this statistic includes the most common building in Europe: low rise single family residence, which is not comparable with the high-rise building structure prevailing in China.

Question 5: what is the difference between rock wool and slag wool?

Answer: rock wool and slag cotton belong to different products.The main component of slag cotton is slag, which has the characteristics of high slag ball content, low melting point and acidity coefficient. Therefore, the thermal conductivity of slag cotton is high, and it will have very serious thermal shrinkage when exposed to fire.

Slag cotton can not be used in projects with fire protection requirements.Moreover, slag cotton can not meet the application of external wall thermal insulation composite system, so it should not be used in external wall thermal insulation composite system.

Question 6: is rock wool harmful to human health?

Answer: of course not.Some organizations (such as the World Health Organization) have carried out a large number of studies on whether rock wool fiber is carcinogenic, and the results clearly show that rock wool fiber is not a carcinogen.The results are as follows: “thermal insulation glass wool, continuous glass fiber, rock wool and slag cotton can not be classified as human carcinogens (Category 3)”.The carcinogenicity of rock wool is well known, and these research reports are public.In addition, as far as health issues are concerned, we are not aware of any restrictions on the use of rock wool.

It is worth mentioning that in order to make some foam products reach the B1 level, the flame retardant HBCDD is a PBT substance (persistent, bioaccumulative, toxic substances). The EU chemical agency has decided to include HBCDD in the substance that needs special attention (SVHC).From production to installation and removal, mineral wool (including rock wool) can be excluded as harmful substances.

Question 7: will rock wool production process consume a lot of energy and produce a lot of emissions?

Answer: all or most of the production waste in modern factories can be recycled. After the remaining small amount of waste is treated, the emissions will be reduced to the lowest level.The energy consumption saved by a unit of rock wool in its use is 100 times that in production.About 20 MJ energy is consumed to produce 1 kg rock wool, and at least 85 MJ to produce 1 kg polystyrene board.The raw materials of polystyrene board are basically mineral fuels such as oil and gas, while rock wool only needs to use very common rock (basalt), and its available reserves are almost unlimited.

Post time: Jul-03-2020